take

a closer look

PROMAI

Promai is an AI-powered manufacturing platform that transforms complex engineering documentation into structured, step-by-step production instructions. By bridging the gap between engineering knowledge and the factory floor, it reduces errors, accelerates workflows, and enables scalable, error-free manufacturing.

The Challenge

To introduce a digital system across all stages of production:

from engineering documentation to factory floor execution, that ensures optimal operation and prevents errors before they occur.

Currently, critical engineering knowledge is often locked in unstructured formats like Word or PDF documents, making it inaccessible to factory workers and technicians. This disconnect results in:

-

Human errors during production

-

Difficulty in scaling and standardizing processes

-

Downtime due to unclear or missing instructions

In the engineering documentation phase, the digital system should replace static Word files with structured, easily accessible knowledge. During production planning, it should support the configuration of optimal production lines. On the factory floor, it must provide guidance, ensuring that no steps are skipped.

The Solution

Developed a connected role-based platform that translates complex manufacturing knowledge into clear, actionable steps across the factory lifecycle:

Gen: Allows documenters to input engineering data and build it into clear, atomic steps with materials, part numbers, quantities, and instructions.

Plan: Transforms these steps into production plans across stations and shifts.

Shield: Presents instructions on the shop floor to workers—one step at a time, with built-in validation and confirmations.

Field: Provides real-time fault tracking and maintenance flows for technicians, closing the lifecycle loop.

ux

process

Domain Collaboration & Iterative Testing

We worked closely with two experienced documenters, who regularly interacted with early versions of the product. Their insights were essential for shaping a system that supports precision, speed, and clarity.

Personas

The two main users of the Gen and Shield products represent very different needs, skills, and behaviors.

On one end is the Documenter: highly skilled, detail-oriented, and focused on translating complex engineering knowledge into clear instructions.

On the other is the Machine Technician: a factory worker, performing physical tasks repeatedly under time pressure.

Designing for both required us to balance clarity, speed, and accessibility across different levels of expertise.

the

design

Gen

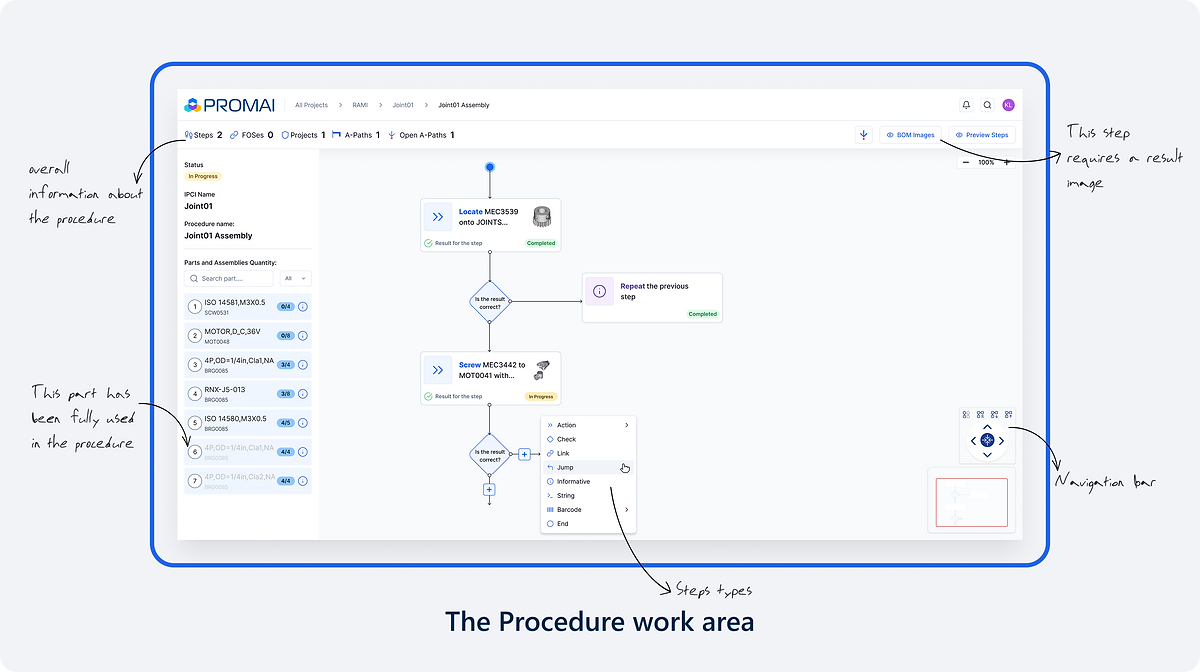

Document complex procedures visually and interactively. Gen helps engineers convert expert knowledge into step-by-step instructions with clarity and structure.

Users: Project manager + Documenter

Plan

Design and validate production flows with smart logic and dependencies. Plan ensures optimal sequencing and consistency across production lines.

Users: Planner

Shield

Deliver controlled, guided workflows directly to the shop floor. Shield minimizes human error by enabling real-time validation and structured execution.

Users: Site/Line manager + Technician

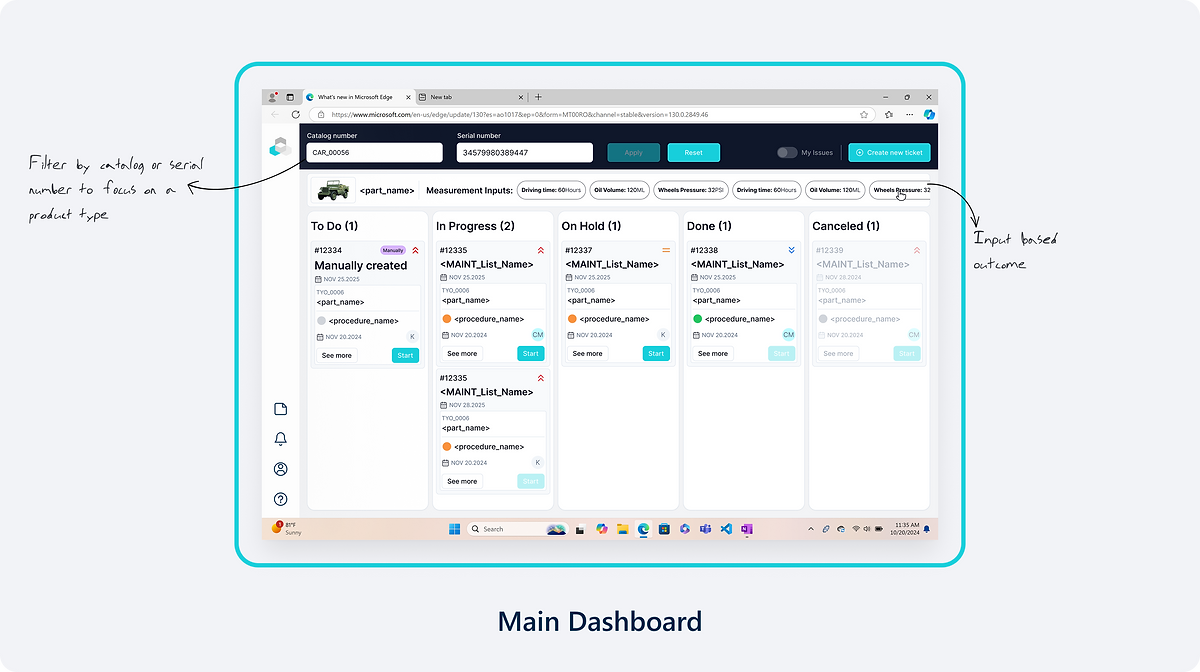

Field

Deliver controlled, guided workflows directly to the shop floor. Shield minimizes human error by enabling real-time validation and structured execution.

Users: Technician

thanks

for reading